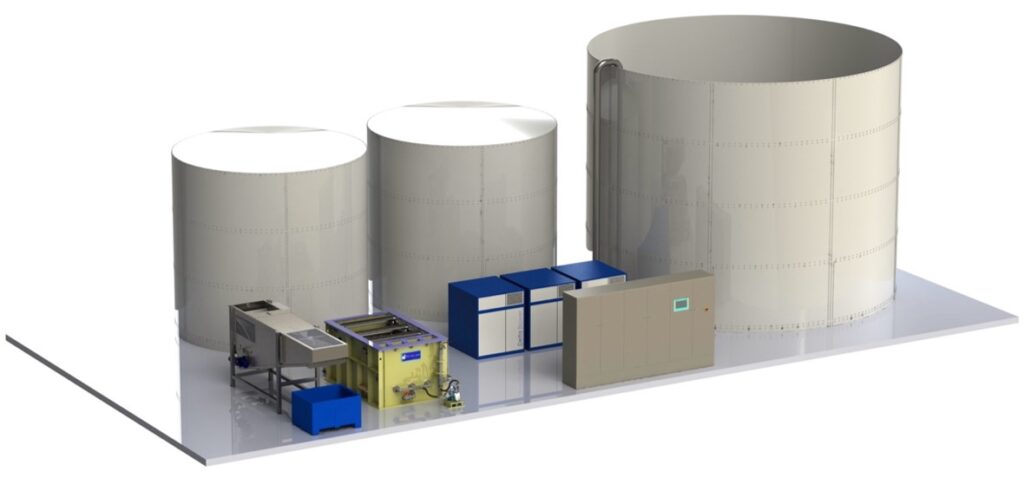

Packaged Systems

Packaged wastewater treatment plants provide efficient, cost-effective solutions for remote and decentralized applications. Our pre-engineered systems are designed to meet specific industry treatment needs within compact footprints by using the latest innovations in screening, biological digestion, membrane filtration, and disinfection.

Custom systems

Specialty Treatment Solutions (STS) is an industry leader in providing custom engineered wastewater treatment solutions for specialized commercial and industrial applications. We provide optimal wastewater treatment designed around the specifications of each client’s site and business needs while enhancing sustainability and meeting compliance standards.

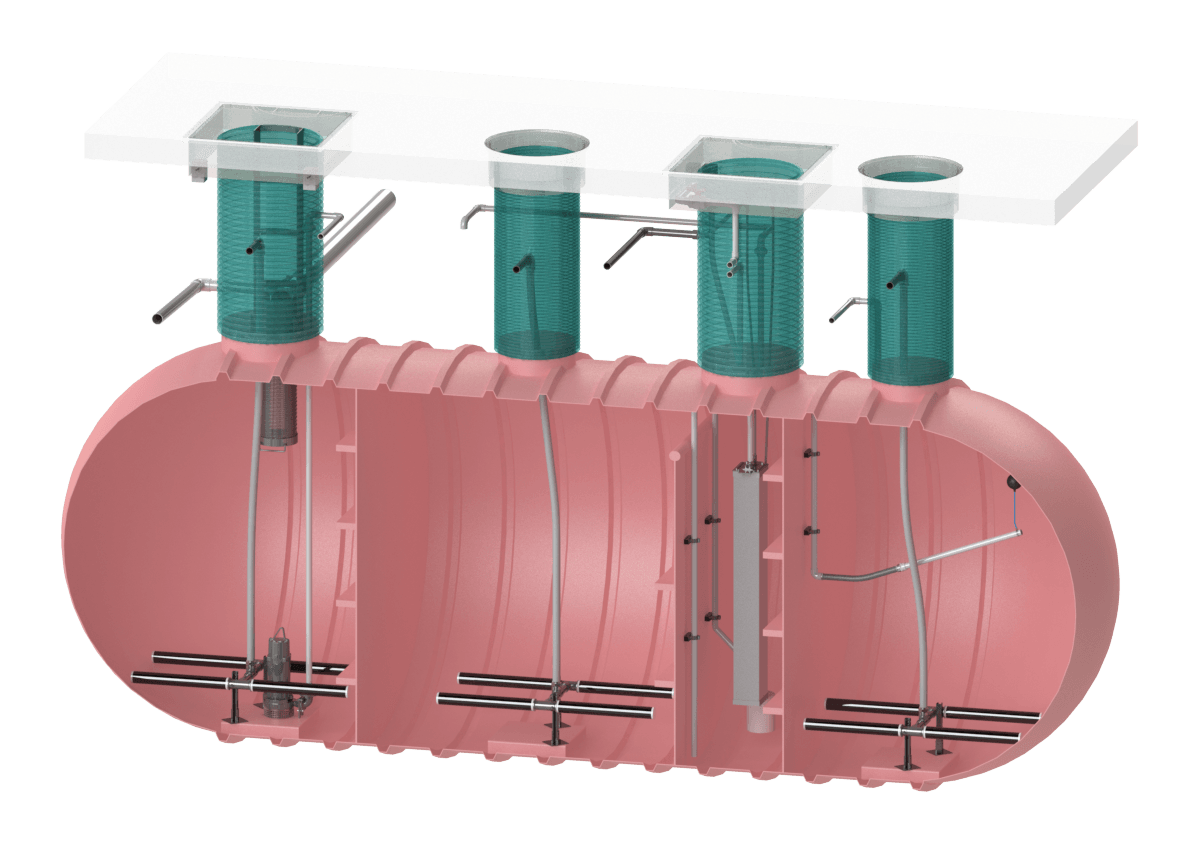

underground systems

Trust Specialty Treatment Solutions to manage your waste water streams and provide water reclamation and reuse solutions that comply with all federal, state and local regulations.

Specialty Treatment Solutions Wastewater Brochure

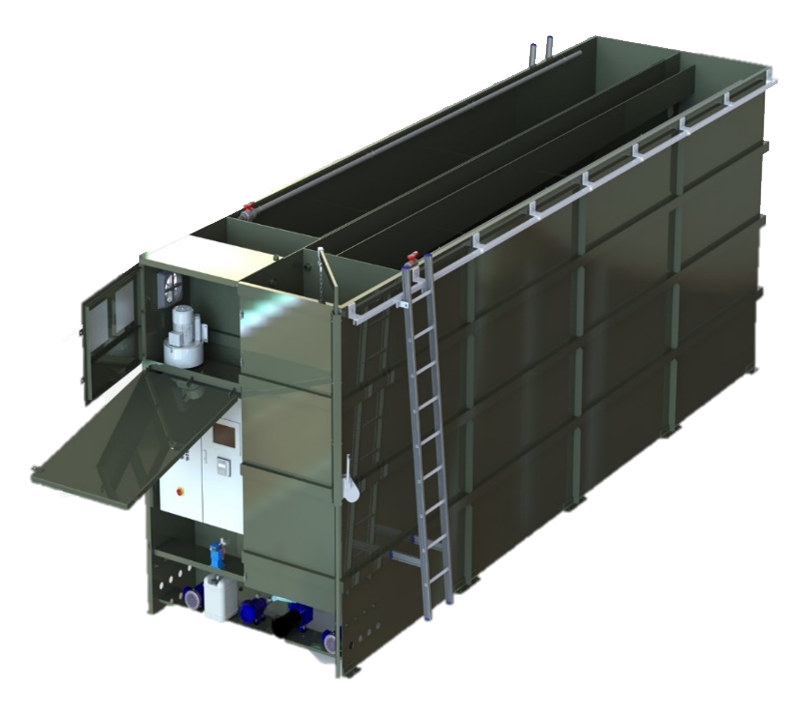

Specialty Treatment Solutions (STS) offers custom designed wastewater treatment systems for any size winery, brewery, food, and industrial wastewater applications. STS’s flexibility and versatility allows each system to be uniquely designed to meet the aesthetic, site needs and treatment requirements of each customer

Approved

Meets and Exceeds Governing Agency Effluent Regulations.

Flexible

Flexible and Aesthetically Pleasing Design. Manufactured in the USA.

Multi-Role

Treats Process Waste, Sanitary Waste or Combined Wastewater.

Small Footprint

Integrated Tank Design. Energy Efficient and Compact Design.

NEW GENERATION

Fiberglass‐reinforced polymer single-piece construction which is corrosion resistant & UV stable.

STS PACKAGES IncludeOther Special Features

Systems That scale

STS systems are modular in design and construction, facilitating ease of installation and allowing for future expansion. Wineries and other industries, typically producing from 1,000 to 20,000 gallons per day (gpd) of wastewater, can take advantage of a pre-engineered system. Larger industries may benefit from an STS custom design to meet their specific needs.

wine industry expertise

Many years of experience in the fields of irrigation, wine production, and wastewater treatment have given our team a vast collective understanding of the complexities and specific requirements associated with winery wastewater treatment.

sts technology

STS is continuously improving the treatment process by researching and adding new technology. STS systems are now equipped with the latest technology in MBBR and MBR innovations.

MBBR Carriers

To ensure the systems can process heavily-loaded wastewater, while still maintaining a small footprint, STS includes a Moving Bed Biofilm Reactor (MBBR) as the first stage in the treatment process.

The MBBR represents a different spectrum in advanced wastewater treatment. In the MBBR process, biofilm grows on small carrier elements suspended in constant motion throughout the entire volume of the reactor. The media is retained in the bioreactor with screens located at the reactor outlet.

Advantages of the MBBR process include better oxygen transfer, shorter Hydraulic Residence Time (HRT), higher organic loading rates, and a larger surface area for mass transfer. In other words, an MBBR provides more efficient processing of concentrated effluent than would otherwise be possible.

mbr cassette

Membrane Filtration – With the increasing need to reuse and recycle process wastewater, STS has included a final membrane polishing step. The physical barrier imposed by the membrane system provides a final filtration of the treated effluent. All models have obtained California Title 22 certification for water purity.

controls

To ensure this simple process functions efficiently and reliably, STS incorporates a smart, internet-based computer-controlled monitoring and management system. This smart web-based control and management system provides unsurpassed reliability and ease of operation, allowing STS technicians to monitor and control the system remotely.